Welded transversal joints

Biquick belts can be delivered in open lengths with the ends prepared for welding on site. Belts longer than 40m are normally delivered with an excess length for ease of handling during installation.

Angle of the welded joint:

90 degrees to the edge of the belt for normal requirements.

80 degrees to the edge of the belt for special high tension requirements.

Other weld angles can be supplied on request.

Riveted joints

Belts of up to 2400mm wide, with a maximum thickness of 1.4mm and a maximum length of 40m,can normally be delivered with both ends ready for riveting on site. Longer belts can also be prepared for riveting but these are then normally delivered with an excess length for ease of handling during installation.

There are two types of riveted joints: Overlapped joints and butt strap joints. Overlapped joints are generally used. the butt strap joint is employed only when a flat joint is required

Find out more about the following topic:

Service instructions

Easy-to-follow instructions on repairing a small dent in a steel belt.

Easy-to-follow instructions on repairing a crack in a steel belt.

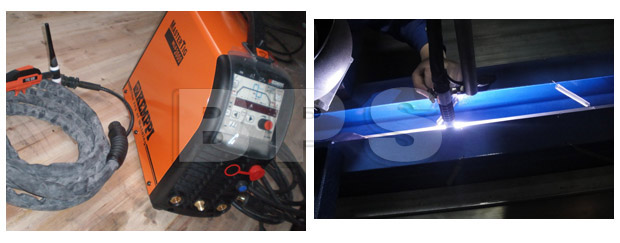

Welding data

technical information and welding data BPS-SB-1100c and BPS-SB-1300c

technical information and welding data BPS-SB-1100SA and BPS-SB-1200SA

technical information and welding data BPS-SB-1600SM

technical information and welding data BPS-SB-1500SM and BPS-SB-1850SM

Frequently asked questions related to steel belt conveying

|