|

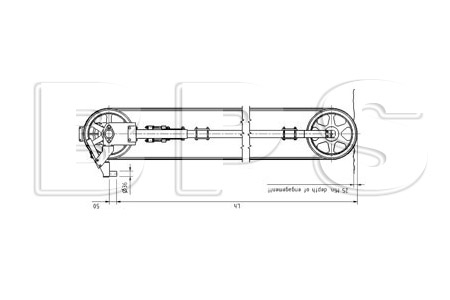

general steel belts are used to continuously separate oil from water. this is a simple solution to the problem of avoiding

oil pollution in water outlets. Included in the delivery of a skimmer is a complete mechanical frame(zink plated or

stainless), a stainless steel belt, BPS-SB-1200SA,and the electrical drive and reducer.

Electric connection points are the connection box on the drive.

Mechanical connection points are the anywhere on the frame, which has holes along ,Its whole length. The units

operate on the principle that adhesion of oil to steel is greater than Water, by having one end of the unit immersed

into the liquid, the steel belt will when traveling upwards, collect an oil film, while the accompanying water will drop

off and enabling a separation rate of almost100%.

The oil is scraped off on both dides of the steel belt and collected in a common same outlet from the skimmer.

The speed of the belt is about 10m/min. The steel belt is tracked in the two sheaves by a rubber rope attached to the steel

belt.

BIQUICK UNVEILS SLICK NEW OIL SKIMMER

Improvements to Biquick’s innovative oil-skimming technology are set to make easier for customers to deploy

these systems in a range of different industries .

Biquick’s steel belt-based oil skimmer is used to separate oil from water and makes use of the fact that the attraction

of oil-to-steel is greater than that of water-to-steel, enabling the steel belt to remove the oil from the water.

The surface of the belt is then scraped to remove the oil collected and this is transported to a container for recycling.

Biquick process systems new oil skimmer is lighter than traditional models, easy to erect and offers a long life span.

another major customer benefit is the use of endless belts. which an be changed on-site without any need for riveting

or welding.

The system is available in a choice of belt widths(100,200and 400mm),in lengths of 1,2and 3m,or as a non-standard

length to match the distance between the inlet of the liquid to be separated and the outlet on the separate liquid.

Applications for oil skimmers are diverse, ranging from oil refineries and food and processing plants to

airports, underground tanks ships’ , and customers will often require unique specification of the product.

The benefits of BPS’s improved oil skimmer include:

Easy belt change (endless belt means no need for riveting or welding on site)

Extended working life of scraper material (due to belt’s lack of weld)

More cost efficient to produce

Lighter design

Easier on –site erection

|

|