|

General description

BPS-SB-1200SA is an austenitic stainless steel with excellent spring properties that in most cases fulfill demands regarding corrosion resistance, mechanical strength, fatigue and relaxation properties.

Compared with standard grade BPS-SB-1200SA offers:

- · higher tensile strength and tempering effect

- · higher relaxation resistance, especially at elevated temperatures

- · higher fatigue strength

- · better corrosion resistance, due to the addition of molybdenum

- · Service temperature .......... .up to 250°C

Chemical composition (nominal) %

| C |

Si |

Mn |

P max |

S max |

Cr |

Ni |

Mo |

Others |

| 0.09 |

1.2 |

1.3 |

0.030 |

0.015 |

16.5 |

7.5 |

0.7 |

- |

Standards: EN: 1.4310

Forms of supply

BPS-SB-1200SA is supplied, as standard, in the cold rolled condition. steel belt an be supplied in coils, bundles, on plastic spools or in lengths. The edges can be either slit or smoothly rounded.

Dimensions

The following range of thicknesses and widths can be supplied as standard.

| Thickness, mm |

Width, mm |

| 0.015 - 1.5* |

2 -3000 |

Tolerances.

See the following tolerance tables

Mechanical properties

Static strength

Nominal values at 20°C (68°F)

| Condition |

Tensile strength, Rm |

Proof strength, Rp0,2a) |

Elongation, A11,3 |

| MPa |

ksi |

MPa |

ksi |

% |

| C |

1100 |

147 |

1200 |

147 |

12 |

| CT |

1200 |

176 |

|

|

|

a) Rp0.2 corresponds to 0.2% offset yield strength.

1 MPa = 1 N/mm2

C = Cold rolled

CT = Cold rolled and tempered, 425°C (797°F)/4 h

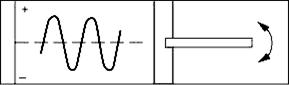

b) Fatigue strenght

Nominal values at 20°C (68°F) in a normal dry atmosphere. The fatigue limit is defined as the stress at which 50% of the specimens withstand a minimum of 2 million load cycles.

Reversed bending stress

Average stress = 0

Bending transversal to rolling direction.

c)Compraision made for different thicknesses and tensile strength levels.

|

Tensile strength,

Rm

|

Fatigue limit, MPa

|

|

Tensile strength,

Rm

|

Fatigue limit, ksi

|

|

|

Thickness, mm

|

|

|

Thickness, inch

|

|

MPa

|

1,0

|

|

|

ksi

|

|

0.039

|

|

1100

|

|

± 580

|

1

|

147

|

|

± 84.2

|

|

1200

|

|

± 590

|

|

176

|

|

± 85.6

|

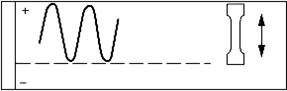

Fluctuating tensile stress

Minimum stress = 0

Specimens parallel to rolling direction.

Physical properties

The physical properties of a steel are related to a number of factors, including alloying elements, heat treatment and manufacturing route, but the following data can generally be used for rough calculations. These values refer to cold rolled material, at a temperature of 20oC(68oF) unless otherwise stated.

Density 7.9 g/cm3 (0.29 lb/in3)

Resistivity 0.9 mWm (35.4 mWinch)

Modulus of elasticity

'as delivered' .........................................approx 185 000 MPa (26 825 ksi)

tempered ............................................. approx 190 000 MPa (27 550 ksi)

Shear modulus

´as delivered´ .......................................approx 71 000 MPa (10 295 ksi)

Specific heat capacity 500 J/kg°C (in the temperature range 50-100°C)

Thermal expansion mean values in temperature ranges (x10-6)

|

Temperature, °C

|

per °C

|

Temperature, °F

|

per °F

|

|

20 - 100 °C

|

15

|

68 - 200

|

8.5

|

|

20 - 200 °C

|

15.5

|

68 - 400

|

8.5

|

|

20 - 300 °C

|

16

|

68 - 550

|

9

|

Thermal conductivity

| Temperature, °C |

W/m °C

|

Temperature, °F

|

Btu/ft h °F

|

|

20

|

15

|

68

|

8.5

|

|

100

|

15

|

200

|

8.5

|

|

300

|

19

|

600

|

11

|

Corrosion resistance

It is very important to avoid corrosion in spring applications so as not to impair spring properties. BPS-SB-1200SA is an austenitic stainless steel and has sufficient corrosion resistance in most applications. However, all austenitic steels of this type are susceptible to stress corrosion cracking (SCC) when in contact with chloride solutions at elevated temperatures.

Welding

BPS-SB-1200SA, like most austenitic stainless steels, has a good weld ability. Welding, however, introduces excess heat into the material closest to the weld that breaks down the structure formed by cold working. As a consequence, this will decrease the mechanical properties of the welded area. The lowest practical heat input, <1.0 kJ/mm, and inter pass temperature for multi pass welding, <100°C, is recommended.

In most cases, the TIG (GTAW) method is preferable. It can be used either autogenously (without filler metal) or with filler metal. In both cases, pure argon (99.99%) should be used as the shielding gas.

When filler metal is used, 19.9.L or 19.9.LSi is recommended..<

|

|