|

Tolerance class, cross bow, % of width

|

H/T condition |

Cold rolled condition |

| P0 |

No requirements |

No requirements |

| P1 |

0.4 |

0.6 |

| P2 |

0.3 |

0.4 |

| P3 |

0.2 |

0.3 |

| P9 |

Acc. to requirements |

Acc. to requirements |

| Hardened and tempered steel belt (H/T), in all tensile strengths and cold rolled steel belt tensile strengths below 1100 MPa. Max. values for entire width range. | Cold-rolled condition in tensile strengths of 1100 MPa and above.

Maximum values.

| Tolerance class |

Width > 50 mm (>2 inch) |

|

Cross bow¹ |

Coil set² |

| P1 |

- |

35 (1.38) |

| P2 |

- |

20 (0.79) |

| P3 |

- |

10 (0.39) |

1)% of width

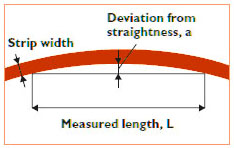

2) mm/300 mm (inch/11.8 inch) | Straightness

The figure below shows how deviation form straightness is defined.

The value in the table give the deviation fron straightness for length of 1 metre. Deviations from straightness can be determined for other lengths using the formula a=b x L2, where

a = the required deviation from straightness in mm for a given length, in m.

b = deviation from straightness according to the table

Conversion between two lengths,

L1 and L2

Hardened and tempered condition - all tensile strength, MPa (ksi)

| Width, mm (inch) |

Max out-of-straigthness, mm (inch). Length 1 m (3 ft) Tolerance class1) |

|

R1 |

R2 |

R3 |

R4 |

| 125- (4.92) |

2 (0.079) |

1 (0.039) |

0.5 (0.02) |

0.3 (0.02) | 1) R0 = no requirement

R9 = according to customer's specification.

Cold-rolled condition - tensile strength < 1100 MPa

1)R0=norequirement

R9=accordingtocustomer'sspecification.

Cold-rolledcondition-tensilestrength<1100MPa

| Width,mm(inch) |

Maxout-of-straigthness,mm(inch). Length1m(3ft) Toleranceclass1) |

|

R1 |

R2 |

R3 |

R4 |

| 125-(4.92) |

2(0.079) |

1(0.039) |

0.5(0.02) |

0.3(0.02) |

| Tensilestrength1100-1800MPa | Mechanicalproperties

| Thetablevaluesfortensilestrengthandhardnessareasdelivered. | BPS-SB 1000SA1200SA 1500SM 1850SM 1300C 1320C

| Standards |

AISI

WNr. |

316

1.4436 |

301,304

1.4310 |

630

1.4542 |

-

- |

1065

1.1231 |

-

- |

Yieldstrength,

R , MPa

p0.2 |

20°C

100°C

200°C

300°C |

890

770

700

600 |

970

910

820

690 |

1320

1270

1150

1070 |

1850

-

-

- |

1200

980

950

890 |

1250

1140

1140

1080 |

| Tensile strength, Rm, MPa |

20°C

100°C

200°C

300°C |

970

890

810

790 |

1200

1020

950

930 |

1500

1360

1290

1210 |

1900

-

-

- |

1280

1220

1210

1170 |

1340

1260

1290

1230 |

| Dynamic strength, MPa |

20°C |

410 |

400 |

500 |

870 |

400 |

440 |

| Weld factor transverse weld Rm/Rm |

20°C |

0.71 |

0.72 |

0.76 |

0.60 |

0.78 |

0.75 |

| Hardness HV |

20°C |

330 |

400 |

470 |

560 |

410 |

380 |

| Density, kg/m3 |

20°C |

8000 |

7960 |

7820 |

7710 |

7880 |

7880 |

| Modulus of elasticity, GPa |

20°C |

182 |

182 |

197 |

210 |

201 |

205 |

| Resistivity, µΩm |

20°C |

0.80 |

0.79 |

0.78 |

0.77 |

0.22 |

0.30 | * Hardness values are converted from tensile strength and should be considered approximate

** Values are outside the HRB range and are for guidance only

A Austenitic stainless steels

| Grade |

UNS |

ASTM |

EN |

Tensile strength MPa (ksi) |

Width mm (inch) |

Thickness mm (inch) |

| BPS-SB-1000SA |

(S31603) |

316LVM |

1.4441 |

800-1100(116-160) |

2-2400(0.08-100) |

0.015-1.5(0.0006-0.06) |

| BPS-SB-1100SMA |

(S30100) |

|

1.4310 |

800-1100(116-156) |

2-2400(0.08-100) |

0.015-1.5 (0.0006-0.06) |

| BPS-SB-1200SA |

(S30100) |

(301) |

1.4310 |

1000-1200(247-177) |

2-2400(0.08-100) |

0.015- 1.5 (0.0006-0.06) |

| BPA-SB-904SA* |

N08904 |

904LVM |

1.4539 |

* |

* |

* | Precipitation hardenable steels

| Grade |

UNS |

ASTM |

EN |

Tensile strength MPa (ksi) |

Width mm (inch) |

Thickness mm (inch) |

| BPS-SB-1600SM |

|

631 |

1.4568 |

1200-1700(174-247) |

2-360(0.08-14.2) |

0.015-3 (0.0006-0.12) |

| BPS-SB-1850SM |

- |

- |

- |

950-1850(138-268) |

2-330(0.08-13) |

0.015-2 (0.0006-0.08) | |

|